WE SPECIALISE IN

WELDING

TRUCK MOUNTED CRANES

HEAVY TRANSPORT

STEEL SUPPLY

MACHINING

CRANE WELD REPAIRS

HYDRAULICS

STEEL DESIGN WORK

FABRICATION

REPAIRS AND MAINTENANCE

HEAVY FABRICATION

CAD DRAWING

Our reputation is built on over 40 years in the industry helping our customers with all their engineering needs. From design to manufacture to repairs, get in touch to discuss your options.

ABOUT MULTI ENG

Your one-stop shop for general engineering services in Silverdale, North Auckland.

With over 40 years of experience on the coast, we can offer the expertise and equipment to design, machine and fabricate to your requirements - From simple repairs to larger projects, we are happy to help.

We strive to complete your work on-time, on budget and have it perform as designed.

Call us today to discuss your requirements.

We stock a range of steel plate up to 80mm, stainless steel and aluminium plate up to 10mm thick and a keep wide variety of bar, pipe, tube and hollow bar on hand. If we don’t have it in stock we can order it in for you easily. Our band saw, plasma cutter, guillotine and CNC press brake handle cutting and folding while our certified welders can take care of fabrication.

We do structural steel work and all the steel and aluminium fabrication components required for both commercial and residential building projects.

Our well-equipped machine shop includes lathes, mills, heavy-duty drills and line boring equipment. Wherever possible we ensure fast delivery and accuracy by doing it ourselves. Parts can be quickly manufactured to fit rather than trying to make unsuitable off-the-shelf parts work.

Not only are we a fully equipped workshop, we also stock a wide range of engineering supplies. We stock nuts and bolts, steel plate, sections, rounds, hollows and pipe, plus lubricants and hydraulic fluid. We stock most sizes of hydraulic hose and fittings and can manufacture hoses to length.

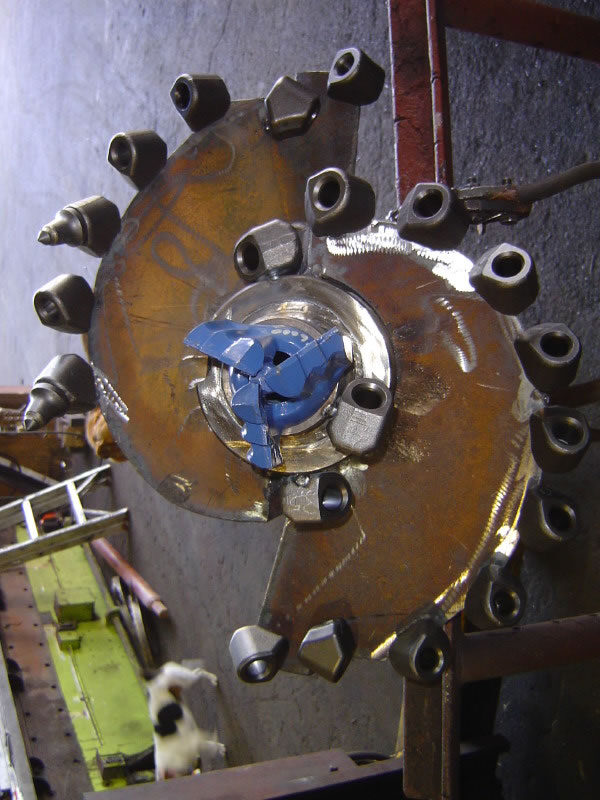

CRANES

Multi Engineering offers specialist services for the maintenance, repair and certification of all brands of truck mounted hydraulic cranes. If you are experiencing leaking hoses, seals, creep or behaviour faults with your crane, call us today. Fixing faults early will almost always save you money in the long term, plus give you peace of mind that your equipment is safe for your staff to use.

WE CAN HELP YOU WITH ALL AREAS INCLUDING:

- Crane hydraulic power system diagnosis and overhaul

- Crane hydraulic control system diagnosis and replacement

- Hydraulic fluid and filter replacement

- Electrical system diagnosis and fault finding

- Solenoid and valve testing

- Hydraulic hose inspection and replacement

- Safety systems

- Crane operation

- Crane to sub frame connections

- Sub frame to truck chassis connections

All truck-mounted cranes require an annual safety inspection. Multi Engineering provides certification-grade inspections and repairs, performed by trained professionals, for all knuckle boom crane brands.

Our inspection process is comprehensive and takes about six hours, including:

-

Cleaning and inspecting the crane structure, hydraulic systems, and controls.

-

Checking tightness of bolts and fasteners, especially those connecting the crane to the truck.

-

Inspecting the crane, sub-frame, and chassis for damage, cracking, or distortion.

-

Assessing the condition of paint and noting any corrosion.

-

Inspecting hoses, hydraulic fittings, oil tank, and fluid levels for damage or leaks.

-

Checking PTO, hydraulic cylinders, and stabilizer legs for issues.

-

Verifying crane stickers, load charts, and range diagrams.

-

Testing or replacing the crane hook with a certified hook.

-

Operating the crane to check wear and function of moving parts.

-

Testing lifting capacity and safety systems.

-

Performing a full load test for any creep or dropping.

If repairs are needed, we'll provide a quote and schedule follow-up work. After repairs, the crane is retested, and a test report or certificate is issued. We also conduct greasing and filter changes to ensure the crane is ready for work.

A copy of the inspection sheet, repair details, and hook test certificate will be provided.

Recent Projects

Opening hours:

- 7am - 5pm

- 7am - 3pm

Address: 57 Foundry Road, Silverdale 0932

Phone: 09 421 1125

Fax: 09 421 1127

Manager: Guy Stucke | Email Guy

Accounts: Email Accounts